(Untitled)

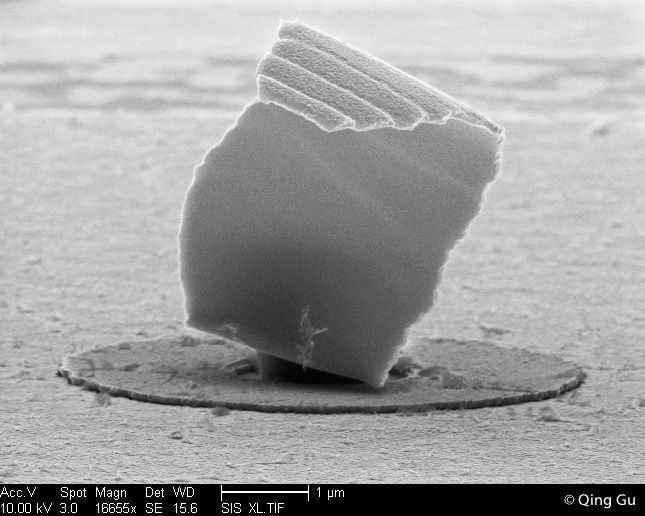

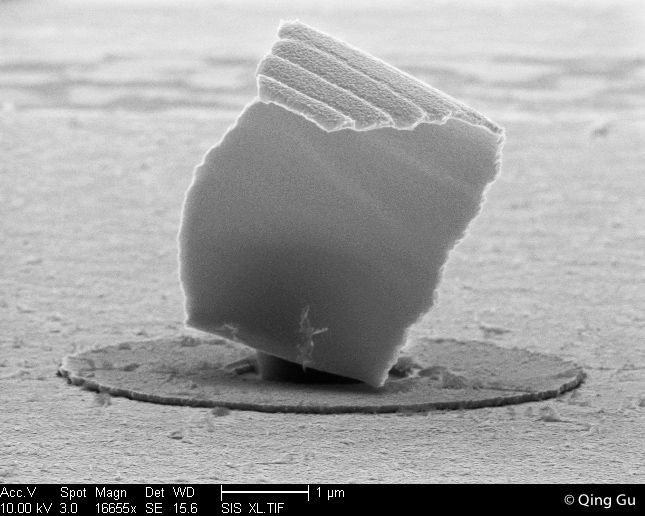

This is the nanolaser equivalent of being smacked in the face with a slab of corrugated roofing during a tornado. There’s one step in making microscopic lasers where you have to peel away metal from much of the substrate, leaving behind pillar-shaped lasers surrounded by small metallic patches. These lasers are much too small for tweezers - you could fit about 1000 of them side by side on a tweezer tip - and so everything has to be done by chemical treatment, which can often be chaotic. Here, a bit of the metal that was supposed to detach and float away instead smacked into one of the laser pillars and stuck.

Laser fabricated and imaged by Dr. Qing Gu of University of California, San Diego